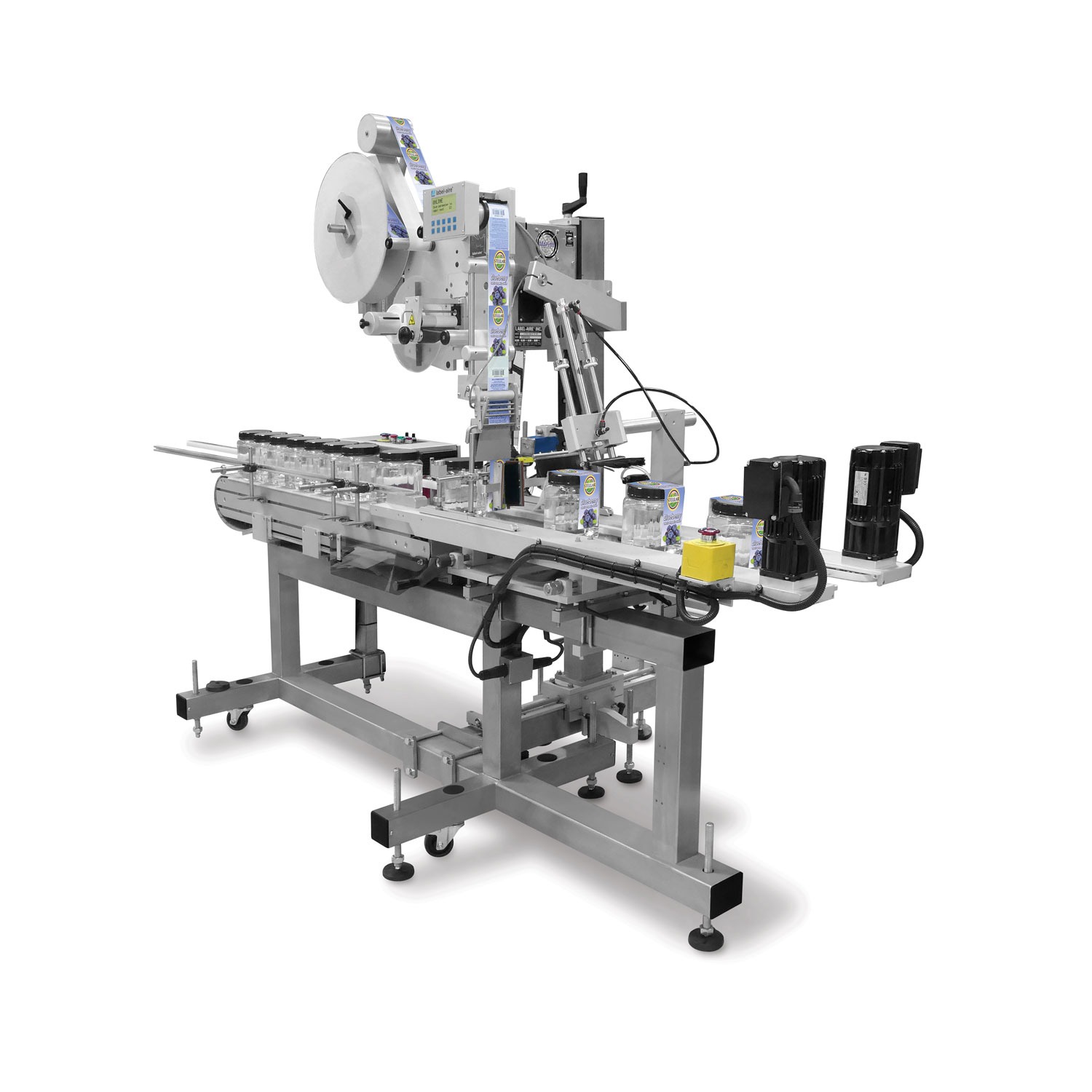

Item: IL6000NHB

The Challenge

A leading food manufacturer needed to effectively apply a label to three sides of various sized containers at a throughput of up to 40 products per minute. Previously the customer was hand applying the label and experiencing reduced productivity due to the required label placement accuracy on the containers without skewing. Hand applying was found to be costly, time consuming and a laborious inefficient process.

The Solution

Label-Aire’s solution was to create a custom inline open frame labeling system to accommodate a 3115-NV applicator. The applicator was mounted upright and above centered on the conveyor system. The conveyor system consisted of an infeed 6000-N table top chain conveyor to convey product to the application point and dual hugger belt outfeed conveyor. A motorized spacer wheel was mounted on the infeed conveyor to create the proper pitch in order to realize the up to 40 products per minute throughput required. Custom dual spring loaded gates were used to help initial tack of the label on the leading panel of the product. A fixed wipe down station wiped the label on the top of the container before proceeding to the trailing panel pneumatic cylinder wipe down system. Label-Aire’s 3-Panel Hugger Belt system proved to be the right solution for the customer’s needs. The system provided accurate label placement, reliability, increased productivity with reduced time and labor costs.